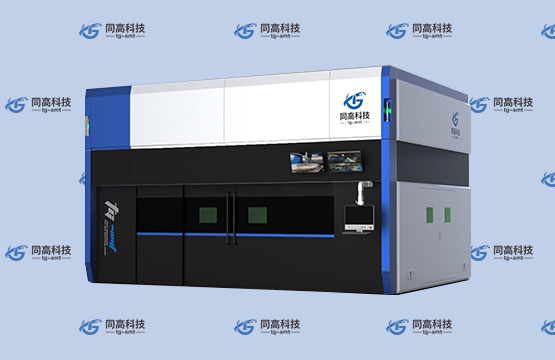

- product name:3D Five Axis Laser Intelligent Processing Center

- category:3D Five Axis Laser Center

- Brand:tg-amt

- manufacturer:tg-amt

- use:Realize large-scale, high-speed, and high-precision machining and manufacturing of complex surfaces and complex configuration parts

- major client:Fengfan Motors, Bintai Machinery, etc

- description

- features

- parameter

- Case

A five axis machine tool based on a five axis linkage motion system and collaborative control of auxiliary axes, equipped with laser cutting, laser welding, laser additive, laser additive and subtractive laser tool ends, and equipped with peripheral equipment such as laser processing auxiliary systems and industrial intelligent control systems. The target product is based on a five axis linkage motion system, loaded with various advanced laser processing techniques, and flexibly switched on the same platform. The processing width can reach 4000 * 2000mm, and it can achieve complex processing with high speed (single axis linear movement of 100m/min) and high precision (repeated positioning accuracy of 0.02mm).

Through five axis linkage and auxiliary axis collaborative control, as well as laser cutting, laser welding, laser additive, and laser additive/subtractive processing processes, the large-scale, high-speed, and high-precision processing and manufacturing of complex curved surfaces and complex configuration parts are achieved, meeting the application needs of large-scale or high-end manufacturing industries such as automotive engineering, aerospace, and military industry.

Based on the high-speed and high-precision linkage control of the five axis platform and the auxiliary axis, as well as the intelligent laser processing center for multi process switching, we design a supporting filler conveying device and a high-frequency and high-precision spatial 3D monitoring and sensing system, and develop an expert system and production control platform based on the cloud platform to achieve multi process and multi parameter laser intelligent processing.

Five axis machining format 4000 * 2000mm, linear speed 100m/min, acceleration 10m/s 2, The accuracy is 0.05mm, and the frequency and accuracy of the processing monitoring and tracking device are 3kHz and 0.02mm, respectively. The linkage control response frequency is 1kHz, and the system is equipped with laser welding, cutting, additive, and composite processing processes. The process and equipment switching time is ≤ 10min.

Previous:None

Next:None

English

English 中文

中文